The Rise of China Precision CNC Parts in Modern Manufacturing

In today’s rapidly evolving manufacturing landscape, the importance of precision engineering cannot be emphasized enough. Among the leaders in this space is China, renowned for its high-quality CNC parts that are integral to various industries. This article delves into the benefits, applications, and competitive edge that China precision CNC parts offer to businesses worldwide.

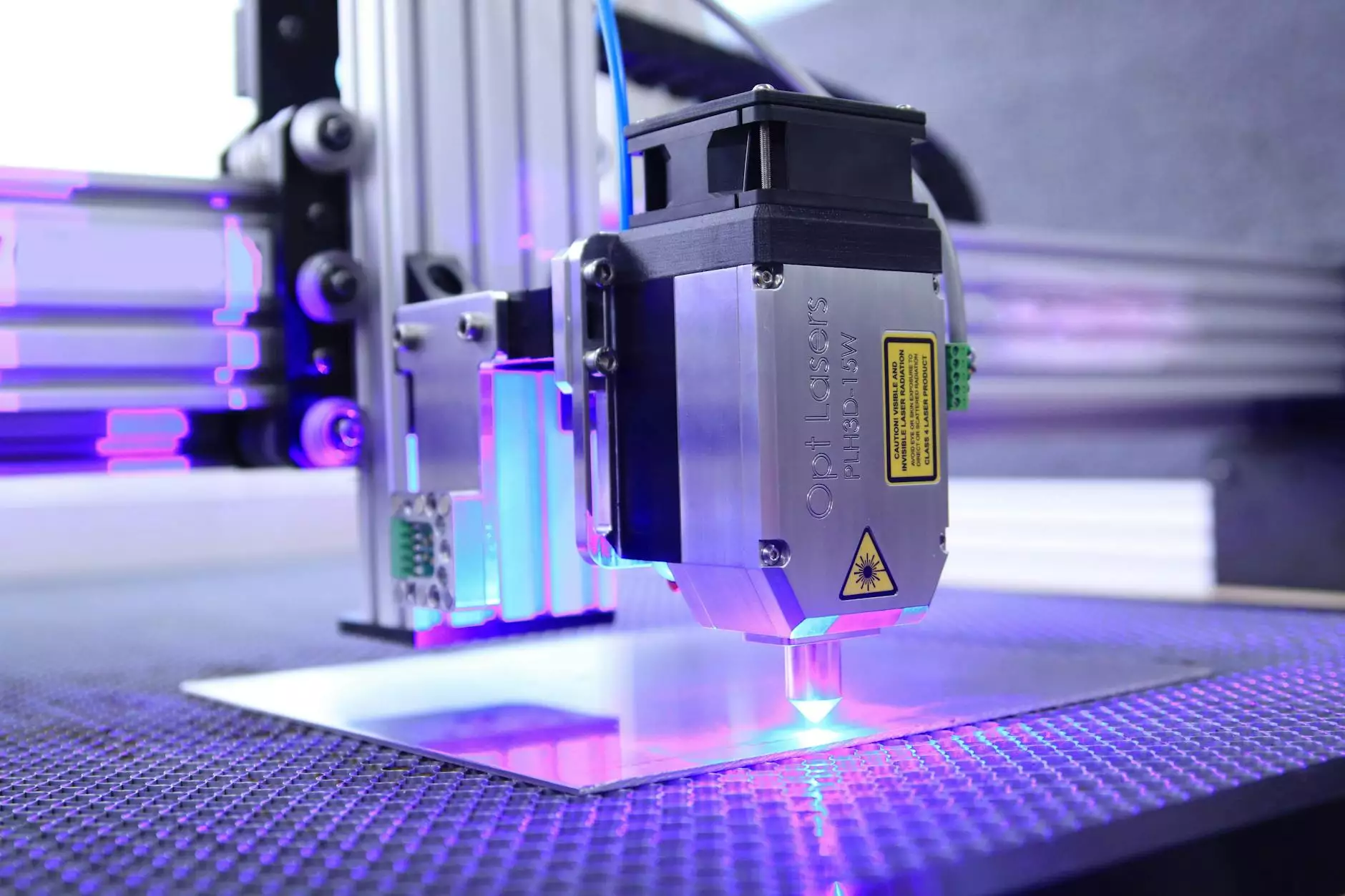

Understanding CNC Machining

CNC, which stands for Computer Numerical Control, is a method used to control machine tools using a computer. It plays an essential role in the precision engineering domain, enabling the production of components with intricate designs and tight tolerances. The use of CNC technology facilitates:

- High Accuracy: CNC machining can produce parts with tolerances as tight as ±0.001 inches, ensuring that every component fits perfectly in assembly.

- Repetition: Once a CNC program is loaded, parts can be produced in large quantities while maintaining uniform quality across the board.

- Complex Geometries: CNC machines can handle complex designs that would be nearly impossible to achieve manually.

The Advantage of Sourcing CNC Parts from China

When it comes to sourcing CNC parts, China has become a powerhouse due to several strategic advantages:

Cost-Effectiveness

One of the most significant benefits of sourcing China precision CNC parts is the cost savings. Thanks to lower labor costs and a well-established manufacturing infrastructure, companies can obtain high-quality parts at a fraction of the price compared to other countries. This allows businesses to maximize their budget without compromising on quality.

Skilled Workforce and Advanced Technology

China boasts a skilled workforce trained in modern manufacturing techniques. The country's investments in technology and education have led to advancements in CNC machining, enabling manufacturers to produce parts that meet international standards. This combination of skill and technology translates to:

- Innovative Solutions: Access to cutting-edge machinery and techniques ensures superior machining options.

- Quality Control: Many Chinese precision manufacturers implement rigorous quality control systems, ensuring that every part meets the required specifications.

Faster Lead Times

In the fast-paced world of manufacturing, time is of the essence. Companies in China have optimized their production processes, allowing for shorter lead times. This efficiency not only helps businesses meet their deadlines but also aids in enhancing overall customer satisfaction.

Applications of China Precision CNC Parts

The versatility of China precision CNC parts enables their use across various industries, including:

Aerospace Industry

CNC parts play a crucial role in the aerospace sector, where precision and reliability are paramount. Components such as brackets, housings, and turbine parts manufactured in China are widely used in aircraft and spacecraft, benefiting from:

- High Strength-to-Weight Ratios: These parts are often fabricated from lightweight materials, enhancing fuel efficiency.

- Strict Compliance: Chinese manufacturers adhere to stringent aerospace regulations to ensure that their products meet industry standards.

Automotive Industry

The automotive industry relies heavily on precision CNC parts for everything from engine components to interior fittings. Benefits include:

- Customization: CNC machining allows for tailored solutions to meet specific design requirements, enhancing vehicle performance.

- Durability: High-quality machined parts contribute to the longevity and efficiency of vehicles.

Medical Devices

In the medical field, precision is non-negotiable. China precision CNC parts are vital in the manufacture of medical devices, including:

- Implants: Precision parts are crucial for the fit and function of implants.

- Surgical Instruments: The demand for reliable surgical tools has led to increased use of CNC parts.

Quality Assurance in CNC Manufacturing

Understanding the importance of quality assurance, many manufacturers in China employ various strategies to maintain high standards:

Quality Control Systems

Implementing comprehensive quality control systems involves:

- Inspection Equipment: Using advanced tools for measuring and assessing each component's integrity.

- Process Audits: Regular audits ensure that manufacturing processes meet established guidelines and standards.

Certifications

Many Chinese manufacturers hold international certifications that validate their processes, such as:

- ISO 9001

- AS9100 for aerospace

- FDA approval for medical devices

Choosing the Right Manufacturer for China Precision CNC Parts

Selecting the right manufacturer is critical to achieving high-quality results. Here are some essential tips:

Research and Reviews

Conduct thorough research on potential manufacturers. Look for reviews and case studies that demonstrate their ability to deliver quality parts consistently.

Request Samples

Do not hesitate to request samples before placing a large order. Testing samples can provide insights into the manufacturing quality.

Communication and Support

Effective communication is vital in ensuring that your specific needs are met. A manufacturer that provides excellent support will help streamline the production process.

The Future of CNC Machining in China

The future of CNC machining in China looks promising, with advancements in artificial intelligence and automation paving the way for even greater efficiency and quality. Key trends to watch include:

Integration of AI and Machine Learning

By leveraging AI and machine learning, manufacturers can optimize their processes, predict issues, and reduce downtime, leading to better quality and lower costs.

Sustainability Practices

The growing emphasis on sustainability influences manufacturing. Many Chinese manufacturers are adopting eco-friendly practices, reducing waste, and offering recycled materials for CNC machining.

Conclusion

In conclusion, China precision CNC parts are integral to modern manufacturing across various industries. With their cost-effectiveness, advanced technology, and rigorous quality standards, businesses that utilize these components can significantly enhance their production capabilities. As the industry progresses, the focus on innovation and sustainability will likely position China as a leader in the global CNC machining landscape for years to come. Adaptability and foresight will ensure businesses can continue to thrive through collaboration with Chinese manufacturers, staying ahead of the competition.

For businesses looking to incorporate high-quality CNC parts into their operations, collaborating with a reputable Chinese manufacturer like Deep Mould (deepmould.net) offers a gateway to unlocking enhanced production efficiencies and exceptional product quality. Embrace the potential of China precision CNC parts today and experience the difference in your manufacturing journey.